Food safety is the utmost concern in the sector. All types of contaminants are dangerous to the health, but the metal ones are the worst as they can lead to physical damage. That’s why magnet trap food safety is one of the best ways of eliminating ferrous metals in food contact machines. The aim of this essay is to outline five different applications of magnet traps aimed at prevention of food spoilage and contamination.

- Preventing Metal Contamination in Food Processing

The first usage of magnet traps lies in prevention of metal contamination in food processing units. This contamination can arise from such places as wearing off of machinery, breakage of some equipment units and parts or even the raw materials. Traps become very important here for they facilitate separation of such ferrous foreign objects from the final product in the course of production.

This is done by placing the magnet traps in the correct positions at the production points where they are most needed. It minimizes levels of metal contamination and guarantees that any food products consumed are safe.

- Maintaining Compliance with Food Safety Regulations

Food safety regulations, such as those set by the FDA and HACCP, require strict measures to prevent contamination. The use of magnet traps helps businesses comply with these regulations by providing an effective method of metal detection and removal. Regular inspections and maintenance of magnet traps ensure that food products remain within safe consumption standards, reducing the risk of costly recalls and legal issues.

- Protecting Processing Equipment from Damage

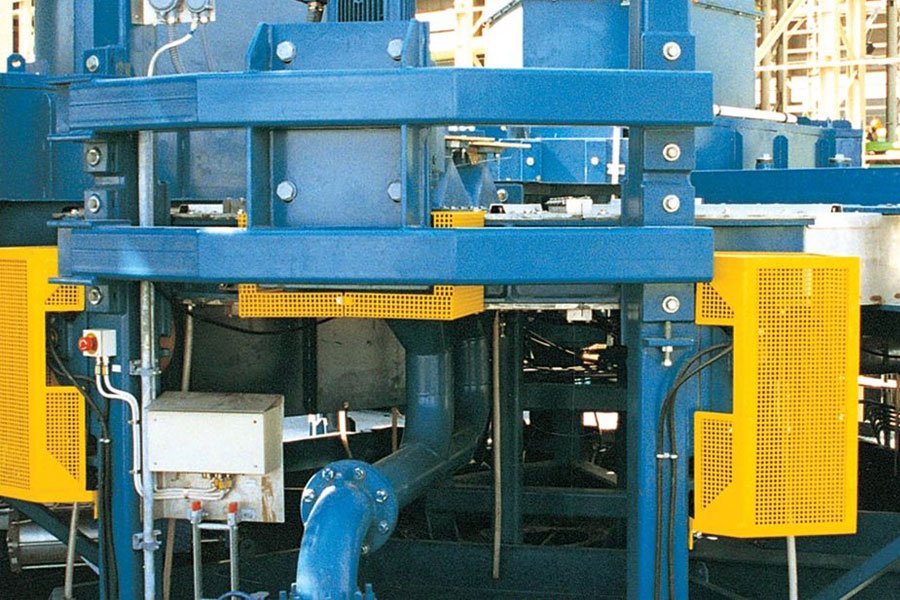

Metal contaminants do not just pose a health risk; they can also cause severe damage to food processing equipment. When small metal fragments enter machines such as grinders, mixers, and conveyors, they can lead to mechanical failure and costly downtime. Magnet trap food safety helps preventing this issue by capturing metal particles before they cause damage, ultimately extending the lifespan of machinery and reducing maintenance costs.

- Improving Product Quality and Brand Reputation

Consumers expect high-quality, contamination-free food products. Even a single incident of metal contamination can lead to negative publicity, loss of customer trust, and potential lawsuits. By using magnet traps, food manufacturers can ensure a higher level of product purity and maintain their brand’s reputation. A commitment to food safety also strengthens customer loyalty and can be a key differentiator in a competitive market.

- Enhancing Efficiency in Food Production

The implementation of magnet traps in food production lines enhances operational efficiency. These devices require minimal manual intervention, reducing the need for extensive quality control checks. With magnet traps in place, food manufacturers can streamline their production processes while ensuring that every batch meets safety and quality standards. This leads to increased productivity and cost savings in the long run.

The use of magnet traps is essential in maintaining food safety, protecting equipment, ensuring regulatory compliance, and preserving brand reputation. By integrating magnet traps into food processing systems, manufacturers can effectively eliminate metal contaminants and deliver safe, high-quality products to consumers.

For businesses looking for reliable magnetic separators and industrial solutions, Unitek offers high-quality products tailored to meet the most demanding food safety challenges. Established in 1991, Unitek has over 30 years of experience in providing combustion burner solutions, gas and water analyzers, and magnetic separators.

With a dedicated workshop in Tangerang, West Java, Unitek specializes in customized magnet trap food safety from machining, fabrication, and system integration to helping industries optimize their operations and maintain the highest safety standards.