For the manufacturing and processing industries, it is crucial to have certain equipment to detect unwanted metal contaminants in their products. To prevent this, multiple industries including packaging, food processing, pharmaceuticals and mining are relying on industrial metal detectors. Here’s everything you should know about metal detectors in industrial settings.

Why Is It Important?

These detectors have one main role which is to identify and at the same time remove any harmful and unwanted metallic contaminants from certain products on production lines. This is extremely important to make sure the safety and quality of the end products will meet the criteria and certain standards, also that they wouldn’t cause any harm to consumers especially for food and pharmaceuticals industries.

How Do They Work?

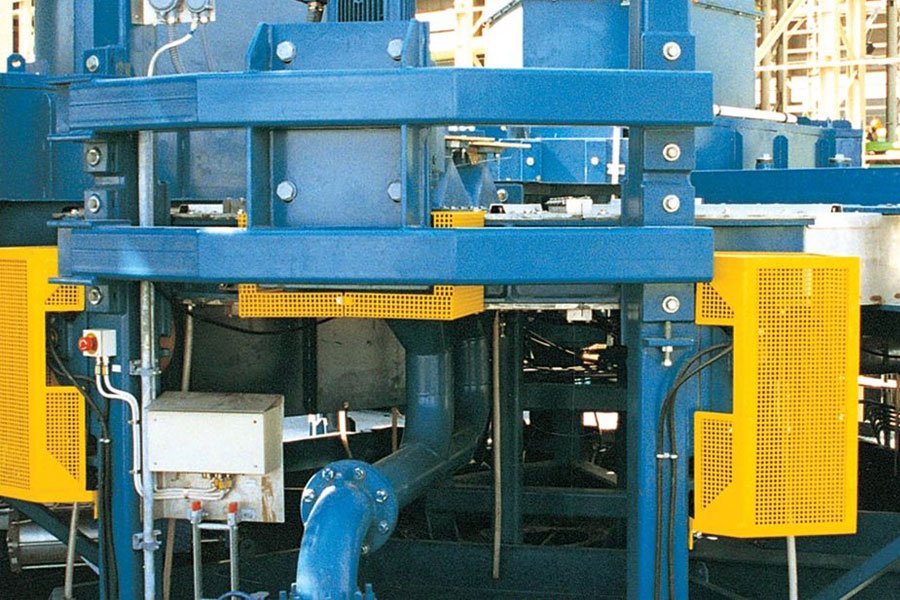

These metal detectors would work based on electromagnetic fields. They will create a magnetic field that would be able to penetrate products that are moving through a conveyor belt. When a metallic object passes through, it would disturb the magnetic field which then would alert the sensors. These sensors would then send a signal to the control system, triggering an alarm or activating a mechanism that would reject or remove the contaminated product from the production line.

There are various metal detectors that would be designed for specific applications. For instance, the pipeline metal detectors will be used in liquids or powder, meanwhile the gravity-fed detectors are more suited for bulk products such as grains. Plus, some detectors would be equipped with certain features such as multi frequency scanning or automatic sensitivity adjustment.

The Benefits

Next, let’s talk about the benefits of having these industrial metal detectors in the factory. The first and foremost, these detectors would help industries to ensure the safety of their customers, especially for food and pharmaceuticals industries. Metal-contaminated products can cause serious health issues which then would make the industries responsible which could end in lawsuits.

After that, removing any metal contaminations would ensure the quality of the products. This would be very crucial to maintain the loyalty of your customers. Once they find that just one of your products doesn’t meet the usual standards, especially when they find a metal inside, then there’s a huge risk they wouldn’t use your product anymore. Metal detectors would make sure your customers don’t switch to competitors.

Not only for the customers, but any metal contaminations could also cause serious issues to the factory’s machinery. They can cause certain degrees of damages that would lead to expensive repairs and replacements which would force the factory to shut down temporarily, also damaging the sales. Metal detectors would prevent maintenance costs and production delays which is why they are so important.

If you’re looking for reliable and high-quality industrial metal detectors, then you should choose Unitek for it. Unitek is a trusted company with more than 30 years of experience and so many high-profile clients are already satisfied with Unitek’s products and services. Go to https://www.unitek.co.id/ now for further details.